About SDMC

SDMC has been developing products and systems helping to enhance the fields of wastewater treatment (biosolids and biomass), robotics, construction, and automation for decades with an impressive success rate. Our experience has helped customers worldwide reduce costs, increase productivity, and improve safety in these fields and beyond.

SDMC is a proud member of the St. Croix Business Innovation Center, based in River Falls, Wisconsin. SDMC works closely with the University of Wisconsin-River Falls and the Chippewa Valley Technical College in the development of our reliable products and systems. Our innovation center is a 12,000 square foot manufacturing facility with ample production space, training rooms, and consultation offices coupled with talented SDMC staff and faculty members.

SDMC is proud to have been recognized as a premier manufacturer by the St. Croix Economic Development Corporation:

Innovative Products and Systems

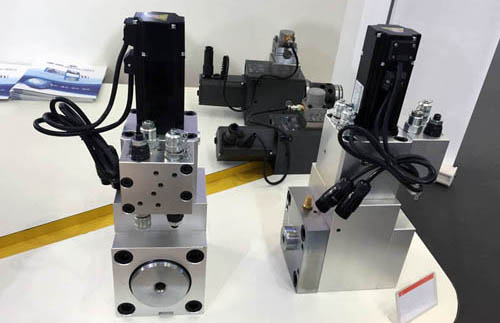

SDMC designs and manufactures reliable products and systems incorporating advanced hydraulic technology, originally developed for aerospace applications. Provided is a listing of our product lines and systems.

Products:

- Electro Hydraulic Actuators (EHA's)

- Standard Double Acting EHA

- Telescopic Double Acting EHA

- EHA with Accumulator (for valve or gate emergency shutoff)

- Super Compact Symmetric EHA

- Digital Control Hydraulic Cylinder

- Associated Control Panels or Embedded Controls for EHA's

Systems:

- Patented Biosolids/Biomass Silo Systems

- Silo Body Structure

- Silo Support Structure

- Sliding Frame and EHA Driven System

- Knife Gate and EHA with Accumulator Driven System

- Discharge Screw Conveyor

- PLC Control Panel

- Level Measurement: Ultrasonic or Radar Level Sensor

- Weighing: Advance Capacitive Weighing Loading Cell

- Micro Lifting System for Robotics

- Super Compact Symmetric EHA

- AC Power or DC Battery Power Servo Motor

- Lifting System for Construction

- Compact Symmetric EHA

- Long Stroke High Force Cylinder

- Embedded Smart Linear Encoder

- Cable or Remote Control

- Heavy Hatch Automation System

- Standard or Telescopic EHA

- Connectors to Hatch

- Control Stand

- Synchronize Hydraulic Cylinder System